3D Printing & Scanning

-

CBM’s CAD software, 3D printing and optical 3D scanning technologies provide the most advanced manufacturing techniques available.

CBM’s in-house workshops encompass leading technology platforms to enable the rapid production of prototype and low-volume components in a variety of polymers and metals.

acne therapy

We are a leading authority within the Advanced Manufacturing industry. Our highly-skilled team of CAD technicians and model makers enable CBM to deliver fast, accurate, cost-effective solutions to your manufacturing requirements in the shortest possible lead times.

CBM’s stringent quality management processes and procedures ensure our outputs are of the highest possible standard.

Additive Manufacture

-

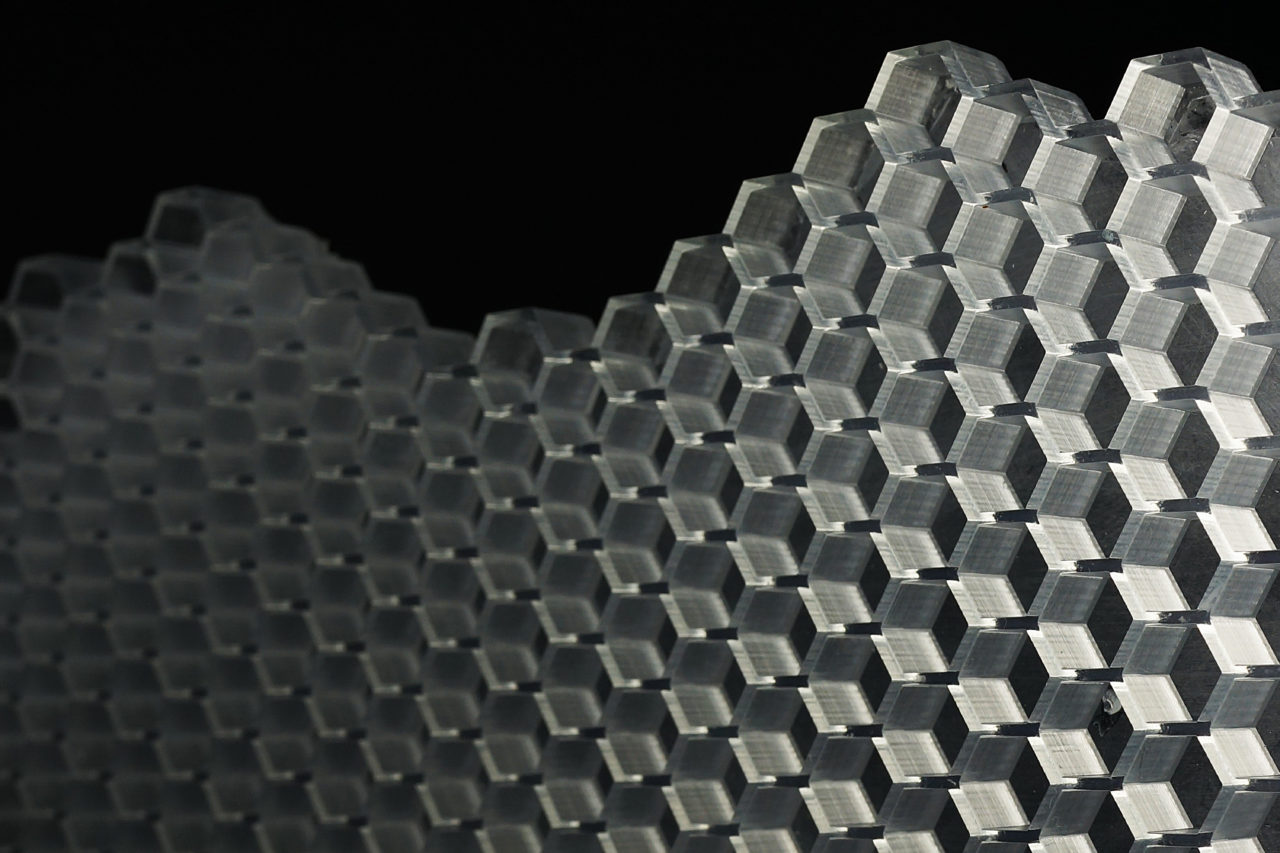

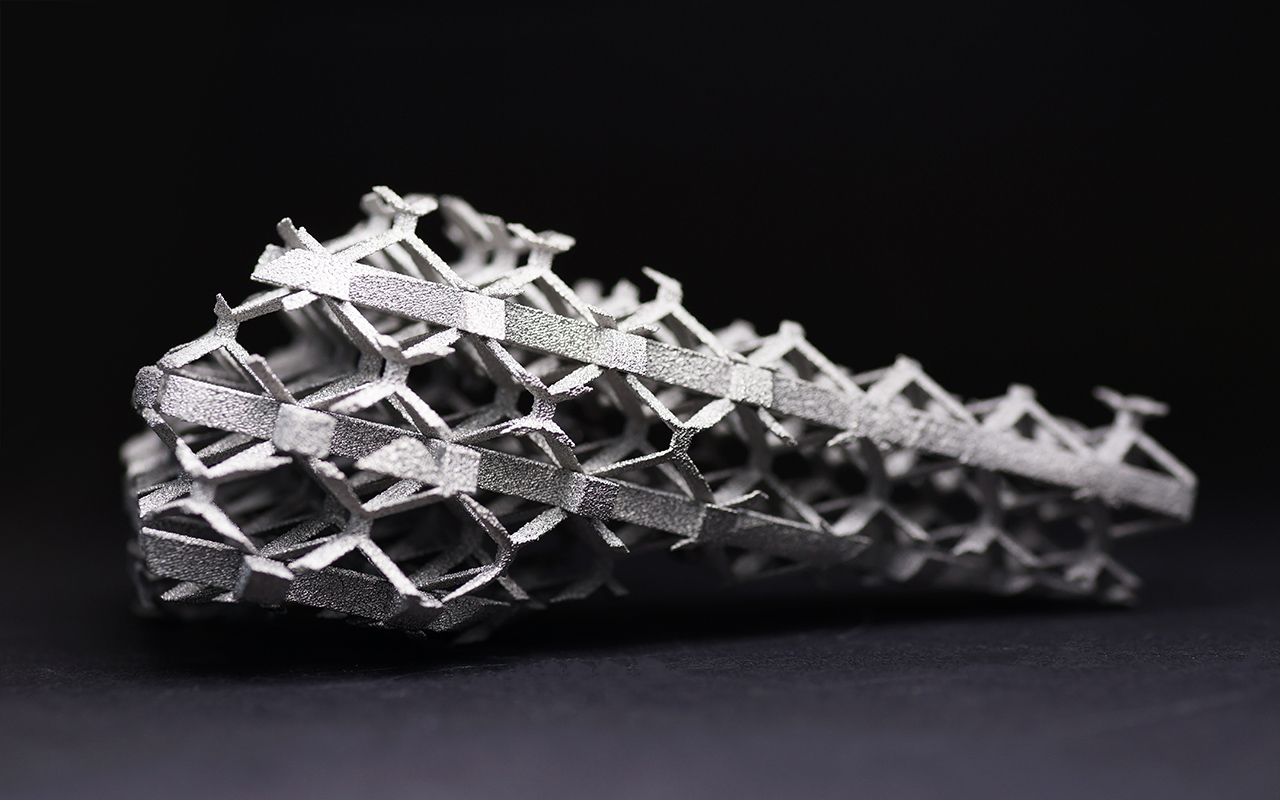

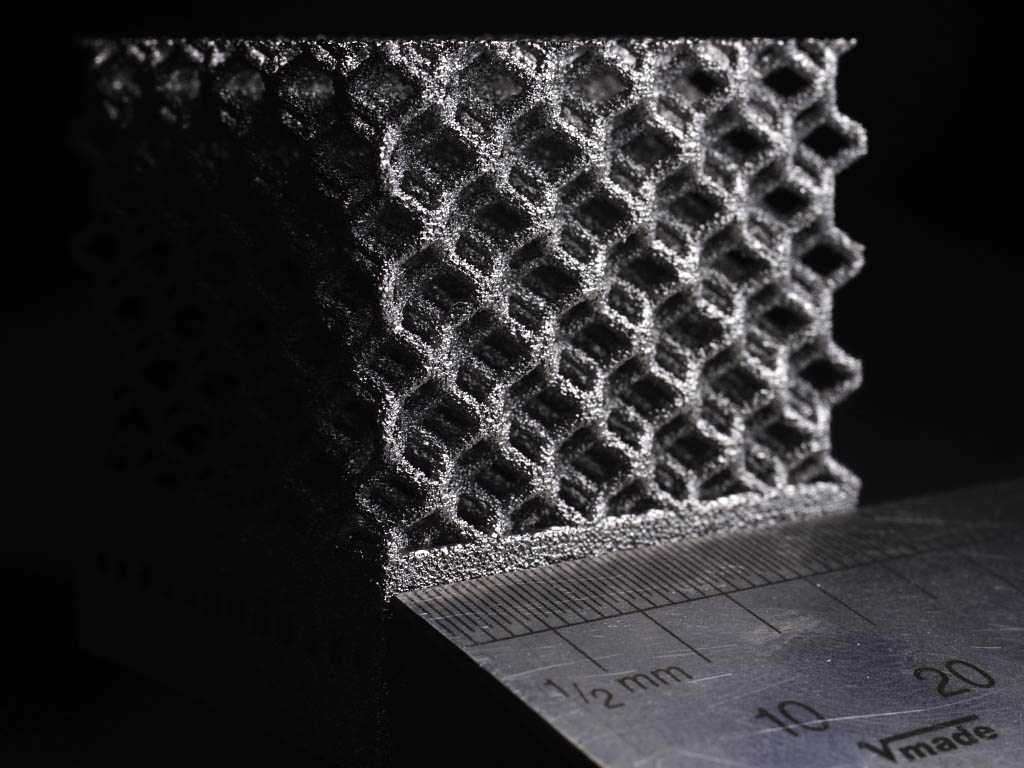

Electron Beam Melting (EBM)

ARCAM Q10

With a build envelope of 200 x 200 x 180mm, CBM's Arcam Q10 can produce small to medium-size components with fine detail. The Q10 has been designed specifically for implant manufacture and developed for easy powder handling and fast turn-around times. The EBM process takes place under a vacuum and at elevated temperatures which results in stress-relieved implants with properties better than cast and comparable to wrought materials. Components are built in Titanium Ti6Al4V ELI which is certified to the USP Class VI standard for biocompatibility and is extensively used for FDA and CE marked implants.

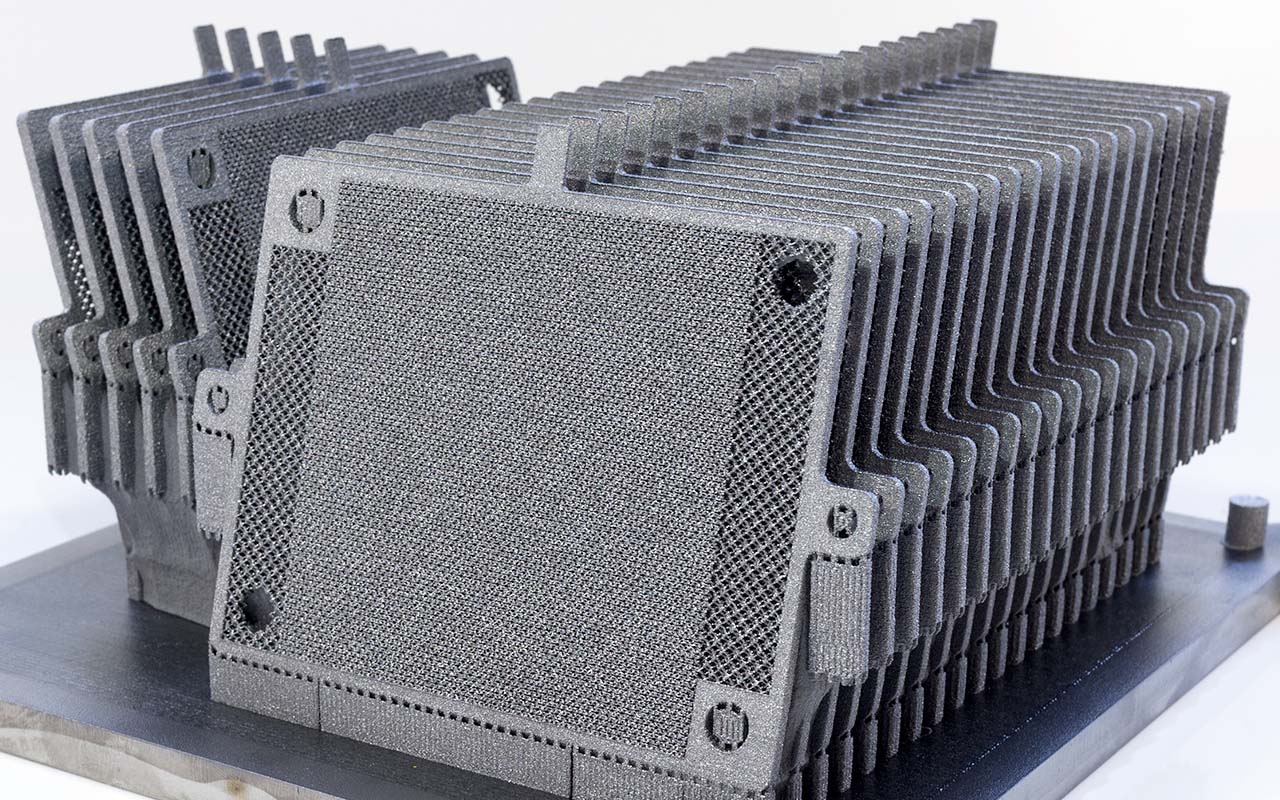

Selective Laser Sintering (SLS)

Formlabs Fuse 1

With a build envelope of 165 x 165 × 300 mm and a layer thickness of 0.1 mm, Formlabs SLS employs Nylon 12 powder to produce high performance prototypes, small batch manufacturing, permanent jigs, fixtures and parts for tooling

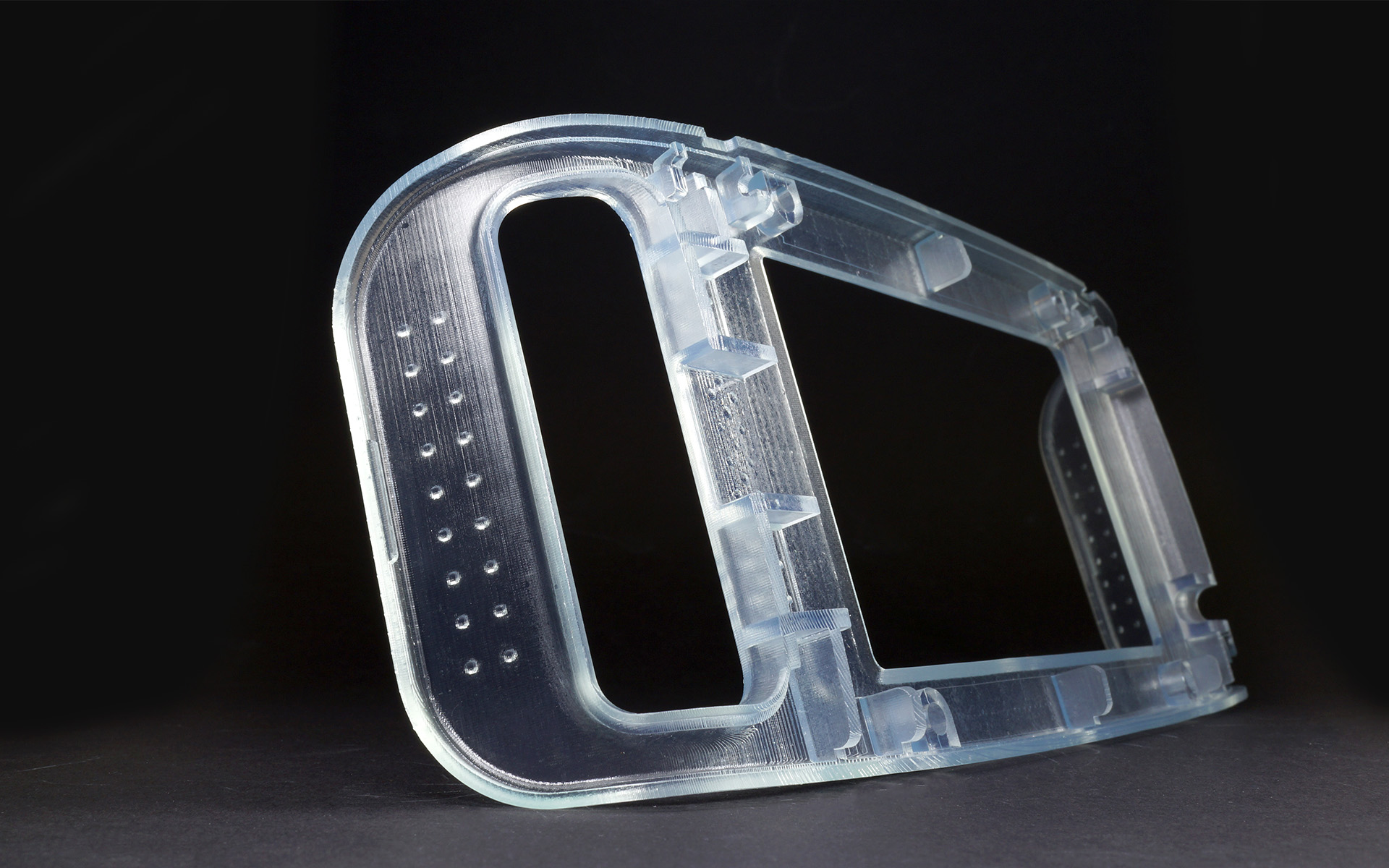

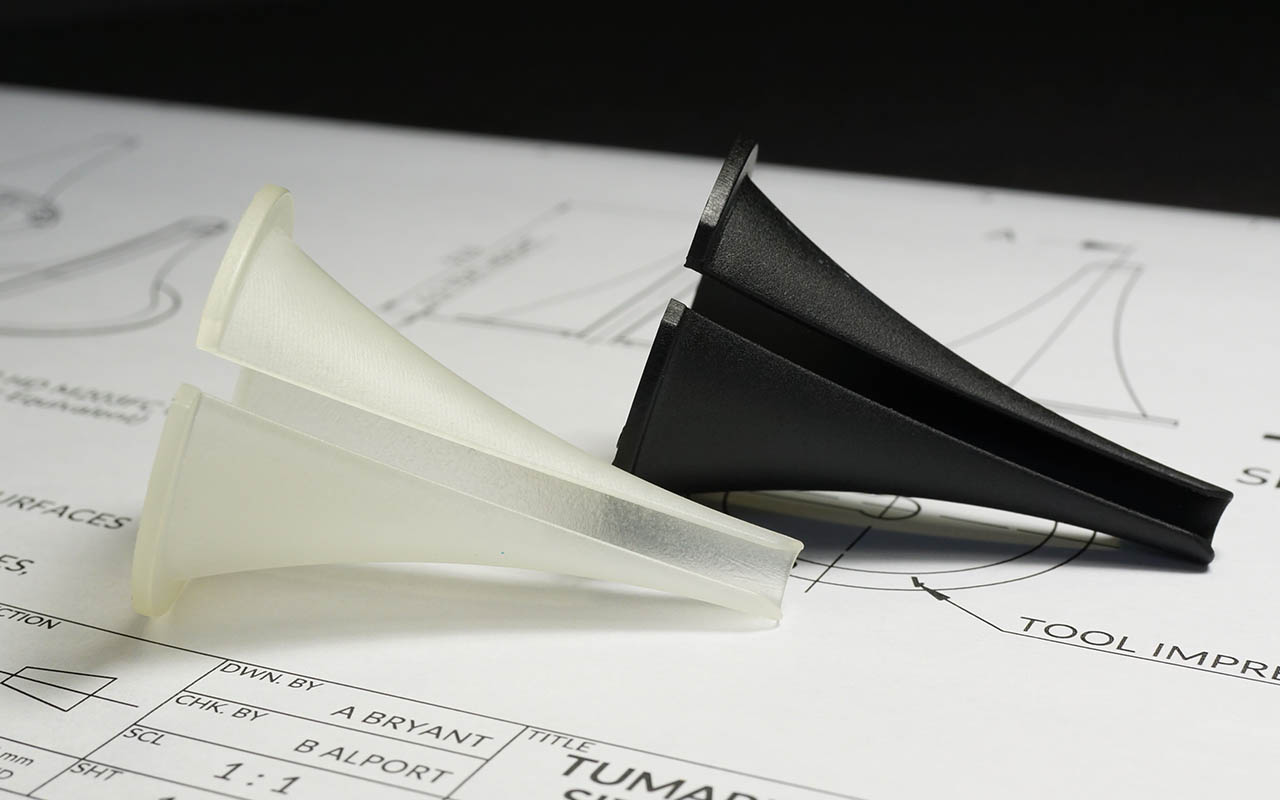

Large Format Stereolithography (SLA)

Raplas PR450 HD+

With a large build envelope of 700 x 700 x 500 mm, the Standard layer thickness is 0.1mm, however the Extreme definition layer thickness can be as small as 0.05mm. CBM's Raplas HD+ can produce large cost effective 3D models in the shortest possible lead times, and runs RaplasPrint Bio and a range of RR60 resins. The RR60 range exhibits properties that mimic ABS.

Medium Format Stereolithography SLA)

Formlabs 3B+

CBM has a Formlabs 3+ with a build envelope of 145 × 145 × 185 mm, producing part with layer thickness ranging between 0.025 - 0.3 mm - CBM employs this to produce patient-specific anatomical models, surgical instruments, medical device prototypes, jigs, fixtures, molds, and end-use parts

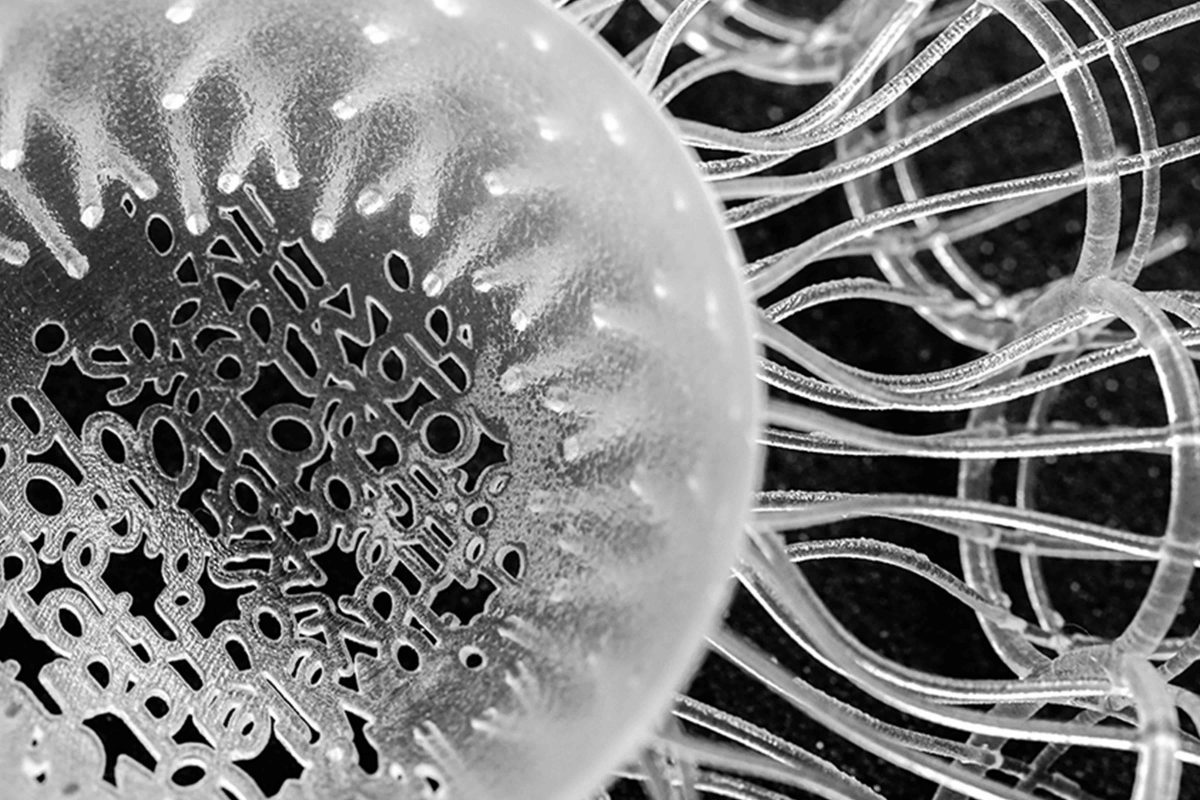

Multi Jet Technology

ProJet 3500 HD MAX

CBM's Pro Jet 3500 HD MAX has a build envelope 298 x 185 x 203mm, capable of producing layer thickness down to 16μ and 1600dpi. In addition to its standard ABS mimic material Crystal, CBM's ProJet is also capable of building in Pro-Cast which has been specifically developed for the production of sacrificial investment patterns. Due to the intricate build capabilities of this technology it is now possible to manufacture geometries that have been previously unattainable using traditional methods.

3D Scanning

CBM offers cutting edge reverse-engineering and 3D scanning services.

Our 3D scanning technology platforms offer state of the art reproduction detail with mesh point spacing down to just 18 microns.

Our 3D scanning technology platforms offer state of the art reproduction detail with mesh point spacing down to just 18 microns.